Repairing Potholes Safely

Awareness about road safety and standards save lives

Repairing Potholes Safely

Potholes have become a serious point of discussion over recent years, they are not only an inconvenience and expense for motorists and municipalities but deadly too. Repairing potholes need to include safety equipment such as road safety cones around the hole, protective wear to give high visibility of the workers, and barrier tape.

According to the Automobile Association, if our roads were properly maintained, road deaths could immediately decrease by about 5 percent.

While it is not a long-term solution, repairing a pothole prevents the road from further deterioration and is a great first initiative for making our country’s roads better and safer for all road users.

A recent High Court decision now allows for private citizens and bodies to perform basic service delivery functions (such as fixing potholes) with taxpayers’ money.

All repairs must first be reported to the relevant department: including 30 days notice of the repairs and obtaining at least two independent quotes.

What causes potholes?

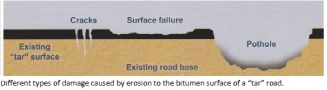

Potholes are holes in the roadway that vary in size and shape, they are the result of interactions between vehicles and water. Poorly or unmaintained roads develop cracks, into which water can seep.

As the weight of cars and trucks continue to pound on this weak spot in the road, pieces of the roadway material begin to weaken, which will cause the material to begin to crack and fall into the hollowed area below, creating the pothole. This problem can become greatly enhanced if the road is being subjected to heavy truck traffic that it was not designed to take.

These factors combined with reduced improvement in preventative maintenance, rainy seasons and a rapidly increasing number of heavy vehicles, can be seen to attribute to the increased number of potholes on our roads in South Africa.

How to repair a pothole?

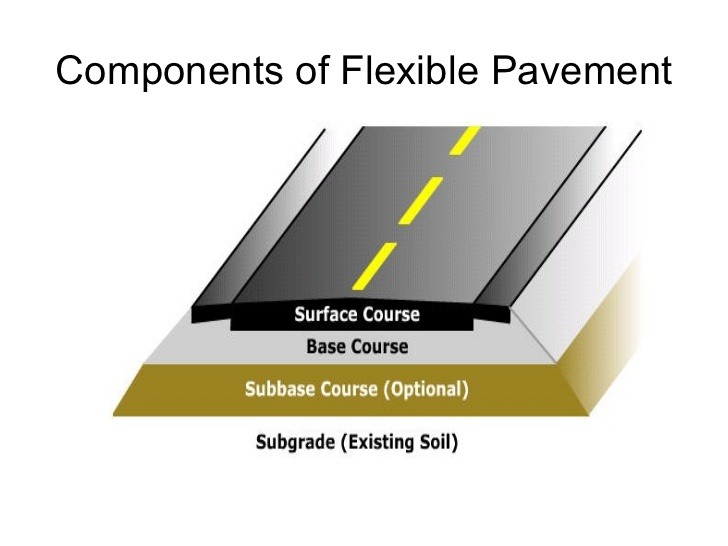

Under all that traffic there are roads, and it’s important to understand what road compromises of if we’re going to know how to fix them. The diagram below illustrates a typical cross-section through a road, in other words, if you had to take a cake cutter and take a big chunk out of it, this is what you’d see.

Understanding road composition

Subgrade (existing soil) – Also called Formation level, this is the native material underneath a constructed road/ the very bottom part of the road. It is also sometimes called the roadbed. This layer is compacted by machines. And is usually about 1250-150mm thick.

Subbase course – This is the layer of aggregate material laid on the subgrade. The materials used may be either unbound granular, or cement-bound imported from a commercial quarry or crusher. This material is sometimes called G4, or G5 material, and is normally about 150 mm thick.

Base course – This layer is located under the surface layer and is the most important layer of a road (it sometimes consists of an extra binder course). It is placed by means of attentive spreading and compacting to a minimum of 95% relative compaction. Generally, the repairs that we will teach you to carry out in this article will not go deeper than this layer, and may even be just in the upper part of this layer. The base course is made using G1 or G2 type materials that come from crushers. Thickness ranges from 100 to 150 mm.

Surface course – This is the road surface sometimes called the Wearing Surface or the Tar. It consists of asphalt concrete that is a construction aggregate with a bituminous binder, which is the prefered material for constructing and maintaining all kind of roads due to its durability and is produced in an asphalt plant.

It is important to note that these guidelines are for fixing shallow surface area potholes only. Underlying problems should be attended to by the relevant professionals otherwise pothole repairs are unlikely to be temporary and will require repeated repair. Likewise, if the extent of the potholes is large or the degree of failure is severe, it is best to contact a specialist engineer to discern whether to rehabilitate parts of the road might be more financially justifiable.

Construction road safety cone 1: Safety First

PPE Requirements:

- Road cones

- Protective and reflective clothing

- Safety goggles

- Reflective Tape

- Hardhat / helmet

Potholes appear in all areas of all types of road, because of this their repair can pose significant danger, once you have identified the types of repairs that you are going to carry out, work should proceed as per the proper safety specifications dictated. Protective clothing includes wearing the appropriate safety vests (brightly coloured clothing), safety goggles and the use of appropriate traffic-control measures such as signage, road safety or construction cones or flags to warn traffic of work in the road. If you do not have any construction cones then use 200 litre drums which are painted white with red and white hazard tape wrapped around them. Make sure that the road is fully open again after dark.

(A copy of the Occupational Health and Safety Act (OHS) is available at all municipal libraries for reference)

Construction cone 2: Identifying the kind of repair?

There are basically three types of repairs that can be done as part of maintenance

- Cracks – Cracking appears due to the settling of soil and the exposure to the outdoor elements, improper mix design for pavement construction. It is the most common form of pavement failure.

- Surface failures as seen above can also be repaired using asphalt products. This guide deals primarily with potholes, and if the surface area has been completely stripped to a depth more than 40mm then you will carry out the repairs described below.

- Never use concrete to repair a pothole. It has different characteristics to road materials. Concrete is a rigid material with no flexibility. It will not bind to the road layers around it and will eventually become loose forming new holes around it.

Construction cone 3: Do the following:

- Mark out the pothole with chalk, spray paint or crayons in the shape of a square or diamond (straight lines can be cut more neatly than round areas. Ensure that the entire “failed” area together with some sound area is included.

- Using a, pick or spade square the pothole off and remove excess tar. Ensure that the depth is even and clean the hole with a broom or stiff brush. Remove all grass and weeds chemically.

- If pothole is deeper than 30mm then loosen the gravel to a depth of about 150 mm below the surface, fill with gravel up to 30mm below the surface to reduce costs and material usage., make sure gravel is moist but not wet to imporve adhesion of the material to the edge of the hole.

- Compact the gravel with a small bomag, hand tamper, mechanical compactor or pedestrian roller until firm like cement. Compact tools can be slightly wetted with water to prevent tools from sticking.

- Remove all loose material.

- Paint the upper surface of the compacted surface and the edges of the hole with bitumen emulsion at rate of 1.2 litres per square meter.

- Wait for the emulsion to break (turn from black to dark brown, and become “tacky”)

- Fill hole with asphalt to roughly 10mm above surface and 20mm overlapping edges of pothole and compact.

- A straight edge should be used to ensure that the final patch is not too high. A 5 to 10 mm “hump” will allow for some traffic compaction without causing a significant effect on riding quality in the longer term. A ;othole surface should not form a depression.

- Road can be opened to traffic immediately. If pothole is fixed at an intersection allow 1-2 hours interval, before opening.

By fixing a pothole on our roads us as motorists are standing up. And the best thing about it it doesnt cost us a cent.

Address

19 Jansen Rd

Nuffield Springs

Gauteng

Call Us

(011) 818 2247/8

(082) 412 7170